Automatic Guided Vehicle (AGV)

Product Details:

- Load Capacity Up to 1000 kg

- Automation Grade Automatic

- Cable Length Wireless Operation

- Frequency 50 Hz

- Remote Control Yes

- Drive Type Electric Motor Drive

- Sensor Type Laser/Ultrasonic Sensors

- Click to View more

Automatic Guided Vehicle (AGV) Price And Quantity

- 10 Piece

Automatic Guided Vehicle (AGV) Product Specifications

- Material Handling, Industrial Automation

- Laser/Ultrasonic Sensors

- Electric Motor Drive

- 0C to 50C

- S.S. 316

- Yes

- 230 V AC

- 50 Hz

- 230 V Volt (v)

- Material handling

- Wi-Fi / Ethernet

- Floor Mounted

- IP54

- Single Phase

- 350 kg

- Industrial Microprocessor

- PLC Control

- Wireless Operation

- Auto Navigation, Safety Sensors, Obstacle Detection

- 7 Inch Touch Panel

- 0.1 1.2 m/s

- Automatic

- Up to 1000 kg

Automatic Guided Vehicle (AGV) Trade Information

- 50 Piece Per Month

- 15 Days

- All India

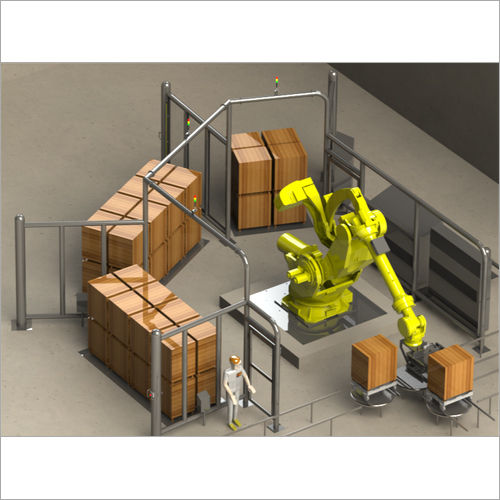

Product Description

Automatic Guided Vehicles (AGV) we deal in are the automatic guided automobiles. These are the portable robots that make use of the radio waves, magnets, vision cameras, and navigation lasers. They are also utilized in the sectors of automotive, electronics and consumer durables. The latest technology of the offered vehicles make them superior to traditional magnetic tapes. Automatic Guided Vehicles (AGV) need not high civil work support. Also, these are useful for transporting the raw materials such as plastic, rubber, metal, and paper. 4

Product details

|

Type |

Material handling |

|

Industry |

Factory And Warehouse |

|

Guided System |

Natural Laser Based |

|

After Sales Service Available |

Yes |

|

Model Name/Number |

AGV |

|

Lifting Capacity |

100 kg. to 300 kg. |

|

Brand |

Janyu-Tech |

Advanced Navigation and Safety Features

Equipped with both magnetic tape and vision guidance, this AGV provides flexible and reliable navigation in various industrial settings. Its electromagnetic brake system ensures precise stopping, enhancing operational safety. Designed for easy integration, it supports automation needs in manufacturing, logistics, and warehousing.

Seamless Charging and Low Maintenance

With automatic dock charging, the AGV minimizes downtime and maximizes productivity. The maintenance-free lithium-ion battery reduces the need for frequent servicing, keeping long-term operational costs low. Its stainless steel build (S.S. 316) offers excellent durability, making it an ideal choice for demanding environments.

FAQs of Automatic Guided Vehicle (AGV):

Q: How does the AGV navigate within an industrial facility?

A: The AGV employs both magnetic tape guidance and vision-based navigation systems, allowing it to move with high accuracy and flexibility along predetermined routes or dynamically adjust as required.Q: What are the benefits of using a lithium-ion, maintenance-free battery in this AGV?

A: The lithium-ion, maintenance-free battery offers reliable performance, extended operational life, and eliminates the need for regular battery maintenance, ensuring continuous productivity.Q: When should the AGV be recharged, and how is it charged?

A: Thanks to its automatic dock charging system, the AGV autonomously returns to its charging station as needed. This ensures it remains charged without manual intervention, optimizing work cycles.Q: Where is this AGV typically used?

A: This AGV is commonly deployed in manufacturing plants, warehouses, distribution centers, and other industrial environments across India, where efficient material handling and transportation are essential.Q: What is the process for customizing the AGVs color or specifications?

A: Customization options, including color and certain specifications, can be discussed directly with the supplier or manufacturer. The team will assess requirements and provide tailored solutions based on your operational needs.Q: How quiet is this AGV during operation?

A: Operating at less than 65 dB, the AGV ensures a low-noise environment, making it suitable for noise-sensitive areas such as cleanrooms and busy warehouses.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+